Providing one-stop intelligent manufacturing services and solutions

We are unswervingly promoting the new four modernizations of intelligent manufacturing: lean, data-driven, automated, and green. As a trustworthy core supplier of AI terminal hardware,

we provide customers worldwide with one-stop intelligent manufacturing services and solutions, including precision functional parts, structural parts, modules, and assembly.

Practicing a green strategy to contribute to global sustainable development

We integrate sustainable development into the core of our corporate strategy, vigorously promoting energy conservation and emission reduction, and incorporating the “3R” principle into every aspect of intelligent manufacturing. We actively respond to the United Nations Sustainable Development Goals and outline a new blueprint for sustainable development.

Upholding long-termism and creating a value ecosystem

We adhere to long-termism and are guided by value symbiosis. We work closely with upstream and downstream partners to share resources, grow together, and achieve more comprehensive service for terminal brands, thereby promoting the sustainable prosperity of the industry.

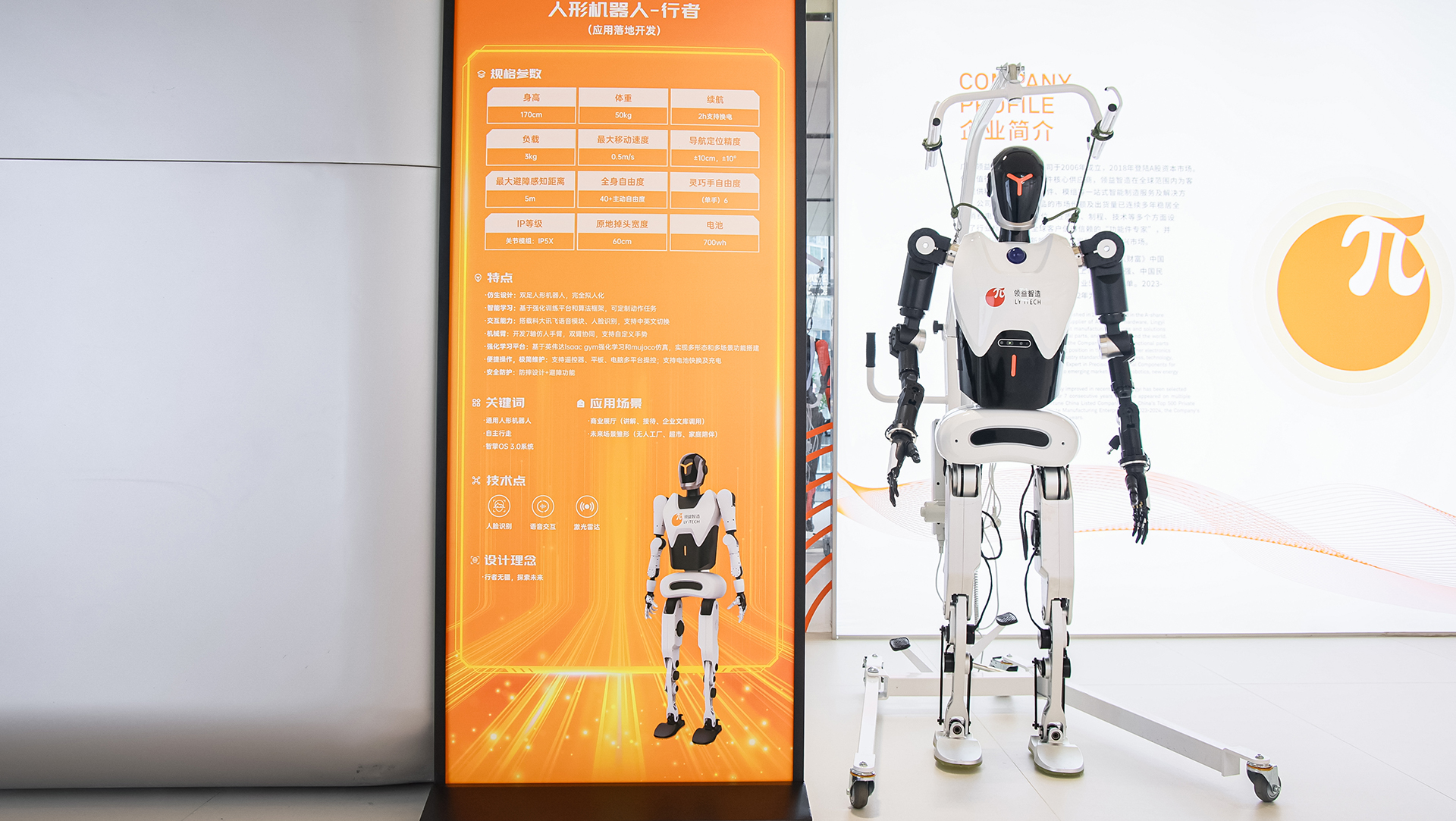

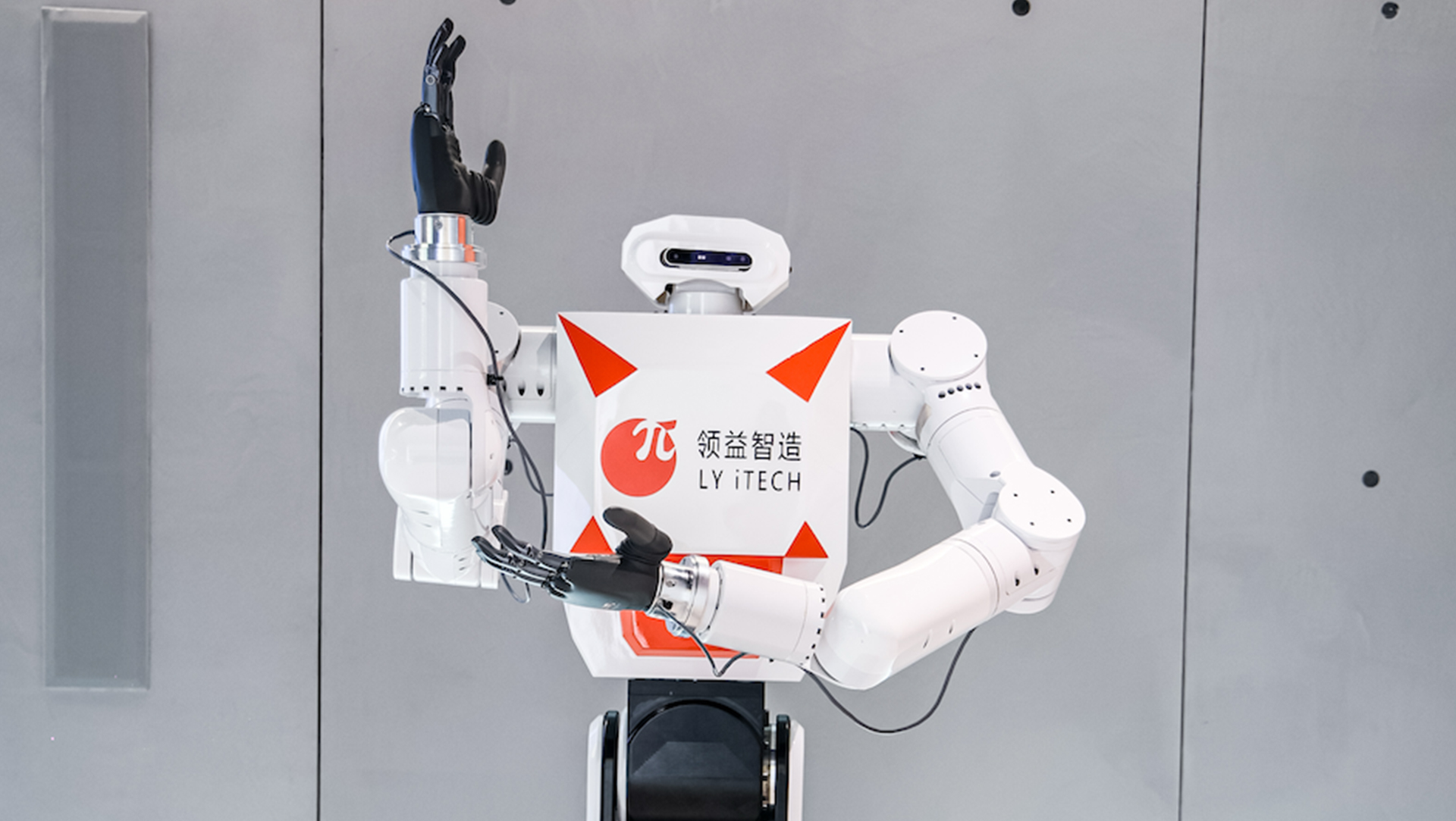

Robot Family

LY iTECH has successfully developed and put into application a series of embodied intelligent products such as ‘Panshi’, ‘Linglong’, ‘Lingyue’, ‘Xingzhe’, and ‘LR5 + Dexterous Hand’.

On August 15-17, 2025, the first World Humanoid Robot Competition, LY iTECH wan two gold medals and one bronze medal in three competitions, which effectively verified the company's strength in the application of embodied robots in real-world scenarios.

Leveraging its comprehensive process technology, automation accumulation, and global layout, the company is expected to achieve early implementation in industrial production fields, such as goods handling and precise electronic assembly scenarios.

LINGYI iTECH (GUANGDONG) COMPANY was established in 2006 and listed on the A-share market in 2018, with stock code 002600

New Media Matrix